CellSense uses patent pending technology.

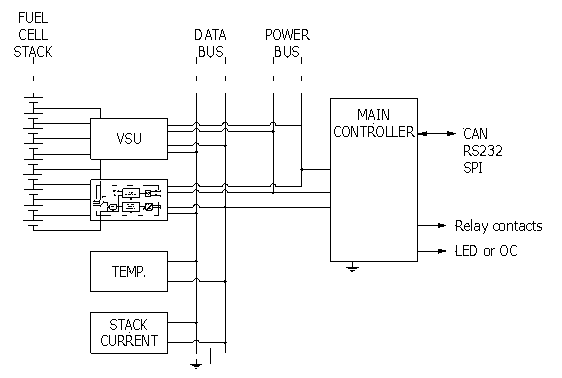

CellSense is built in a modular way. One component in this design is an analog to digital converter that converts the voltages of four adjacent cells to digital information. This is called a voltage scanning unit or VSU. Any number of VSUs are connected in parallel, one for every four cells in a stack. All these VSUs are powered over a common isolated power bus and they send and receive data over a common isolated data bus. The other component in the design is the main controller. Its task is to read the data generated by the VSUs, to treat this data and to generate messages for a higher level controller in the fuel cell installation.

There are several advantages in using multiple VSUs:

- Very modular design, very few unused channels

- High common mode voltage rejection

- Measurements are performed quasi simultaneously (within less than 0.5 msec)

- Very low component count to achieve low cost

- Great flexibility for PCB lay-out in case of custom design

Here is a block diagram of the CVM:

As pointed out, any deviation from optimal operation results in cell voltages dropping low. This means that malfunctions or unsafe situations can be detected by a CVM making it a effective and valuable component in safety, risk and operability assessments.

Possible advantages of the CVM are:

- Safety device to comply with risk assessment

- Lower gas stoichiometry (lower λ)

- Higher availability, better quality of electric power

- Less chance of damage

- Increased life expectancy

- Fast diagnosis in case of damage

- A complete history of on-site stack’s life